It’s definitely do-able, but requires some work in an image editing software. Materialize Functionsįor those of you that have worked with maps for rendering, you know that finding and creating those maps can be a little time consuming. Product Links in the description are typically affiliate links that let you help support the channel at no extra cost.

If so, please consider supporting me on Patreon (click here to support) or by visiting my Support the Show Page!ĭisclaimers: all opinions are my own, sponsors are acknowledged.

#MATERIALIZE 3D FREE#

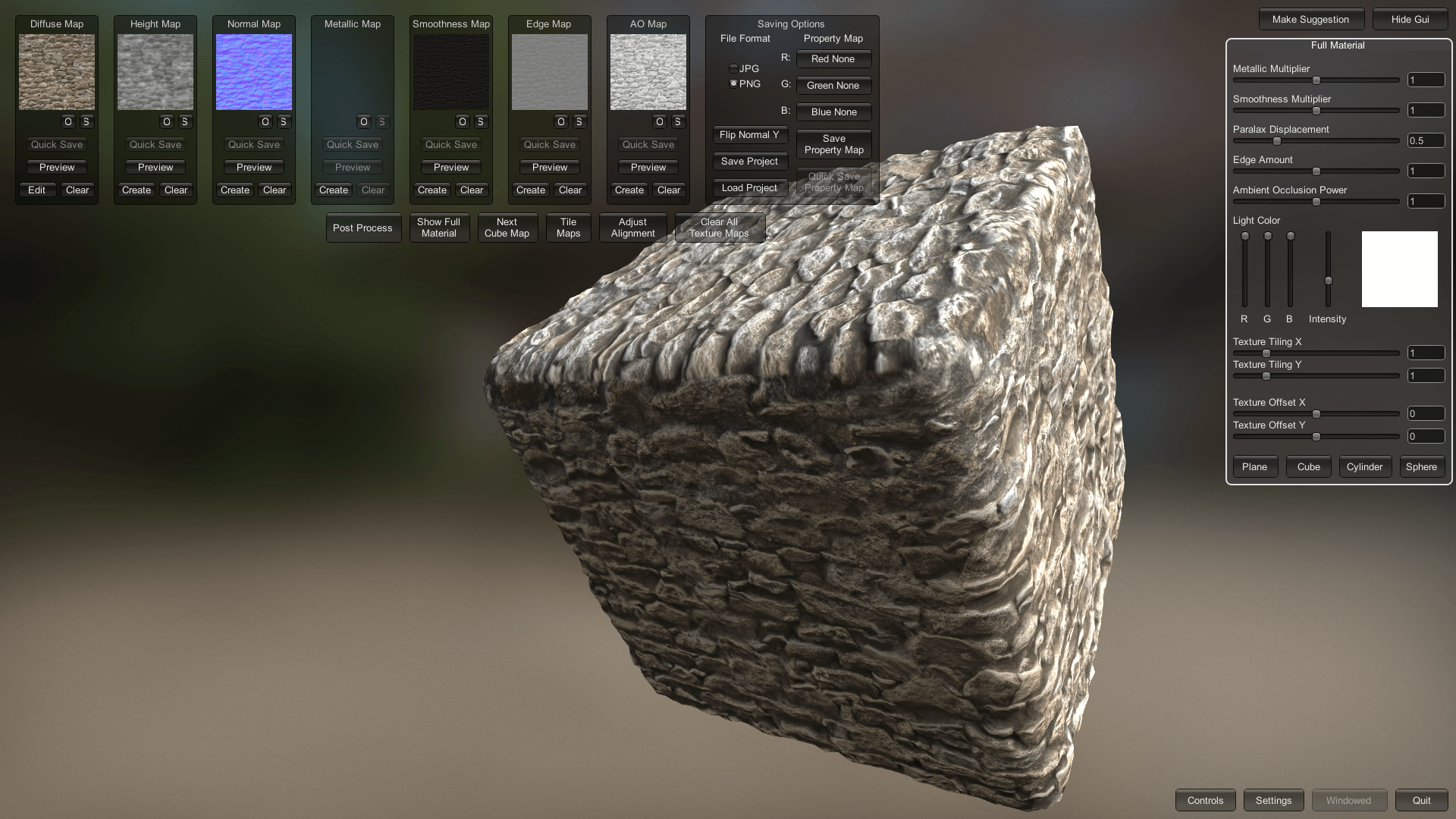

This easy to use, free tool allows you to quickly create textures that include height maps, normal maps, and other maps using just an image file!ĭo you like these SketchUp tutorials and videos? Get your FREE print subscription to TCT Magazine.FREE Texture and Map Generation with Materialize – Easy Texture Creator Want to discuss? Join the conversation on the Additive Manufacturing Global Community Discord. Combining the latest technologies of both companies, it enables significant reduction in production cost as well as excellent printing performance.”

#MATERIALIZE 3D SOFTWARE#

Woo, Suk-Hyung, Chairman of Sindoh said: “This new product also demonstrates the excellent synergy of Materialise Software and the 60 years of hardware manufacturing experience of Sindoh. Furthering its collaboration with Materialise, Each S100 is bundled with Magics Print 25, a Materialise Build Processor and its Control Platform (MCP) and is fully compatible with Magics RP and Streamics.ĭr. Sindoh lists Evonik PA12, BASF Ultrasint PA11, TPU and PP as just some of the materials compatible with the machine. For materials, engineers are able to tweak the machine’s parameters and work with a range of powders, including those with processing temperatures up to 200℃.

The machine is said to offer high productivity thanks to additional features such as a removable build system, the ability to work with variable later thicknesses, and semi-automatic calibration and remote diagnostic maintenance capabilities. The S100 operates with a build volume of 510 x 510 x 500 mm and two lasers, each with a flexible spot size, which cover the entirety of the print bed.

0 kommentar(er)

0 kommentar(er)